CONTOUR is a laser cutter with line-following capabilities, which allows users to draw directly on materials and laser-cut without the need for CAD software or any computer interface.

I designed electronics and led electronic integration of CONTOUR as part of Pink Team in 2.009, MIT’s capstone mechanical engineering design class.

CONTOUR is powered by a Raspberry Pi microprocessor inside the front panel, which is basically a computer on a chip the size of your hand. When the user hits scan, a Raspberry Pi computer captures an image of the cutting bed via a small camera positioned under the lid.

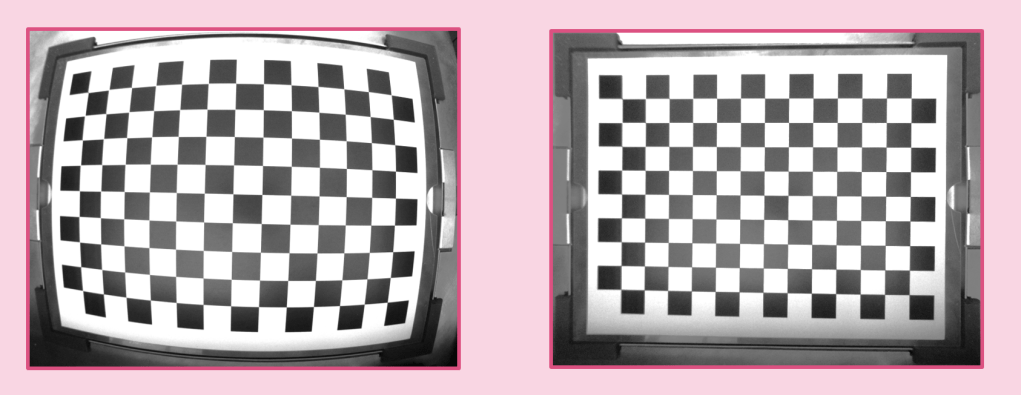

The camera has a fish-eyed lens with a 120-degree Field of View, which allows us to see the entire 9×12-inch cutting bed from only 7 inches away. The raw image from the camera is then run through our undistortion software, which removes the warping of the fish-eyed lens.

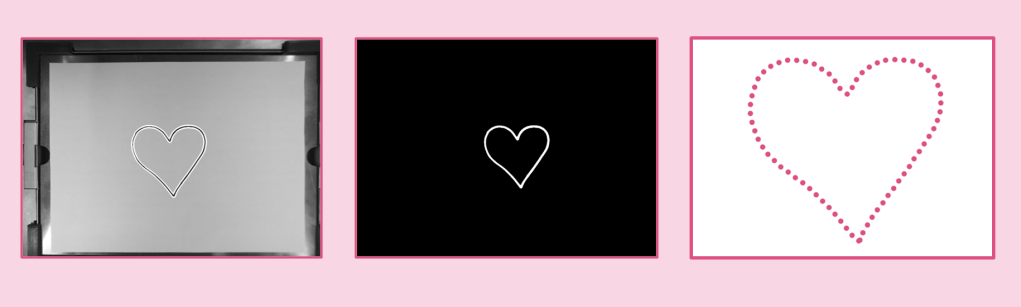

Next, the Raspberry Pi traces the external and internal outlines of the drawing. It finds the centerline and converts that into points. When the user hits cut, the computer sends those points to the motors as a path to follow, and Contour is on its way.

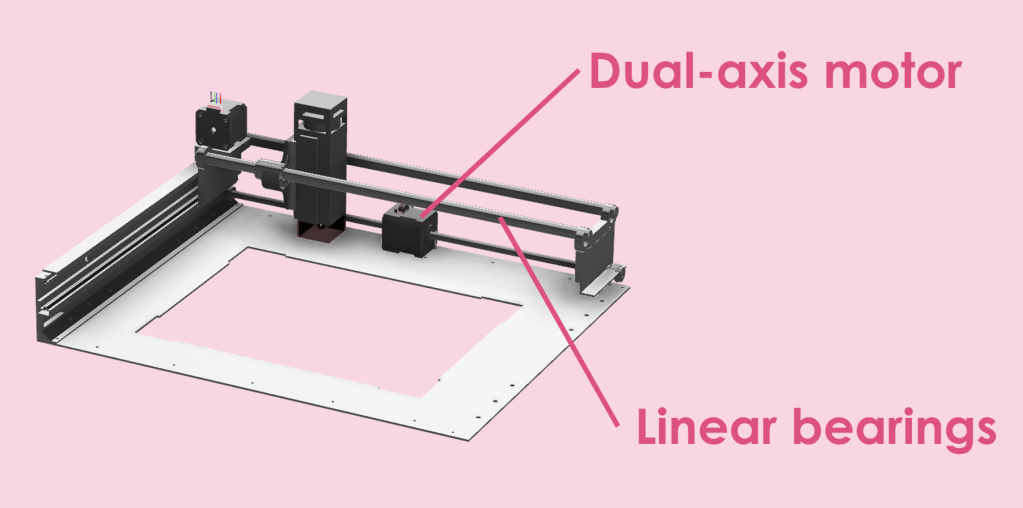

Contour is designed to fit into a small apartment or crowded family home, and our compact gantry system optimizes cutting bed space.

Our stepper motors and linear bearings provide smooth and precise motion. Each motor step is only 0.2 mm, which is three times more precise than the cutting width of the laser.

Our diode laser cuts lines that are 0.6 mm thick, which is equal to the width of a standard ball-point pen. The laser’s power can be adjusted to cut standard crafting materials such as paper, cardboard, wood up to an eighth inch thick.

Burning wood releases smoke, but Contour siphons that smoke away with a built-in fan, which connects to either a ventilation hose or an air filter.

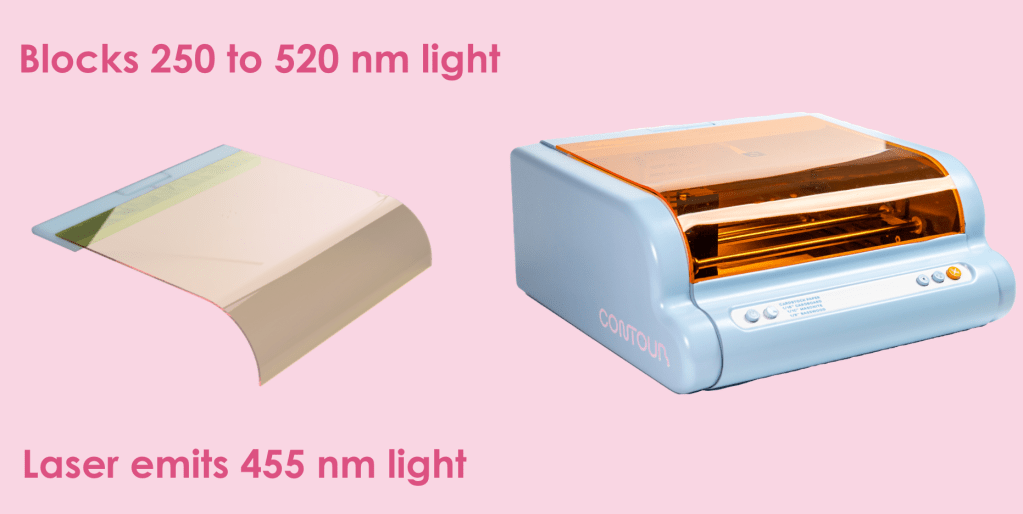

Lasers are bright, but our orange acrylic window protects your eyes from the wavelength of light that our laser emits.

For these safety measures to work, the lid should be closed – but if a user forgets and hits ‘cut’ by accident, don’t worry: there’s a limit switch which triggers if the lid is open, and our software prevents the laser from operating until the lid is closed again.

When Contour is done cutting, all the buttons light up.

We are excited to continue work on Contour’s entrance to the market beyond the scope of 2.009.