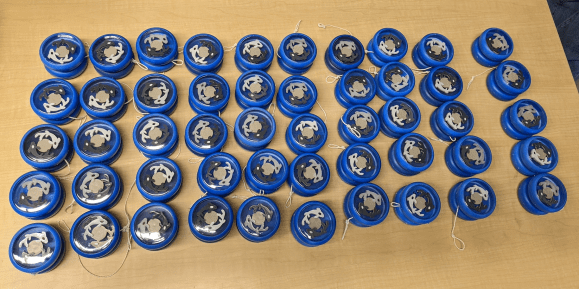

In 2.008, Design and Manufacturing II, our task was to design, CAD, and manufacture 50 yo-yos using injection molding and thermoforming. My team chose to do the Tui-La fish from Avatar.

We designed for a press fit with radial interference of 0.031 in ± 0.001 in. An early challenge we encountered was that the assumed value of thermal expansion was slightly too high, making our press fit too loose. We measured the expected versus actual thermal expansion coefficients, re-machined our molds, and found that our press fits worked well. We later iterated the molds again to add runners for the ejector pins so that no ejector pin marks were left on the yo-yo body.

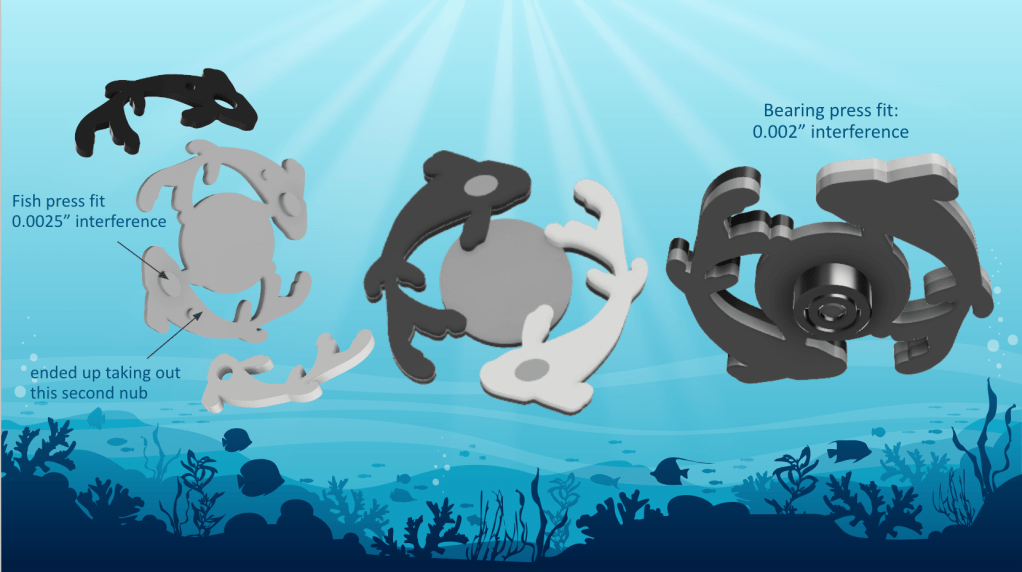

We set the Tui-La fish on a bearing so that they spun when the yo-yo was in motion.